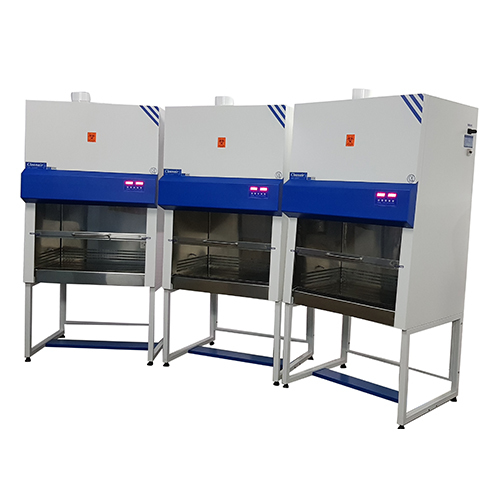

SS BioSafety Cabinet

165000.00 - 290000.00 INR/Unit

Product Details:

X

SS BioSafety Cabinet Price And Quantity

- 1 Unit

- 165000.00 - 290000.00 INR/Unit

SS BioSafety Cabinet Trade Information

- 4 -6 Unit Per Week

- 6-8 Week

Product Description

Biohazard is a contraction of two words- biological and hazard. Infectious agents present a real or potential risk to humans, animals as well as plants directly through infection or indirectly through environmental disruption.

Biosafety levels

The integration of laboratory processes & techniques, laboratory facilities and safety equipment needed for performing operations and prevent the hazard posed by the infectious agents and the lab operations. In Microbiological and Biomedical Laboratories, several biosafety levels are needed to be taken.

Biosafety Level 1

Processes, facility design, safety equipment and construction are right for undergraduate and secondary educational training and teaching laboratories as well as for other labs in which work is carried out with defined, characterized strains of microorganisms that are not hepatitis virus, and exempt organisms under the NIH Guidelines for Research Involving Recombinant DNA Molecules represent those microorganisms that meet such criteria. Many agents that are not linked with diseases processes in humans are, however, opportunistic pathogens and might cause infection in the human beings, including young, the elderly, and immune deficient/ suppressed. Biosafety Level 1 basically represents a basic level of containment in which standard microbiological practices are to be carried out with no recommendation of special primary or secondary barriers, other than a sink for hand washing.

Biosafety Level 2

Processes, facilities and equipment are applicable to several facilities, including clinical, diagnostic, teaching, etc., in which work is carried out with indigenous moderate-risk agents present in the community and linked with human disease of varying severity. The agents can be safely used in activities carried out on the open bench with good microbiological techniques, provided the low likeliness of producing aerosols. The Salmonellae and Toxoplasma spp., Hepatitis B virus, Human Immunodeficiency Virus (HIV) represent microorganisms assigned to this containment level.

Bio-safety Level 2 is suitable if the work has to be done with any human-derived blood, body fluids, tissues, or primary human cell lines where one might be not aware of the presence of an infectious agent. (Laboratory workers who work human-derived materials should refer to the OSHA Bloodborne Pathogen Standard for specific required precautions.) The primary hazards to lab workers working with aforementioned agents may include accidental percutaneous, ingestion of infectious materials or mucous membrane exposures. Workers must take precaution with using sharp instruments or contaminated needles.

Even though organisms periodically manipulated at Biosafety Level 2 are unknown to be transmissible by the aerosol route, processes with aerosol or high splash potential, which may elevate the risk of workers exposure, must be carried out in primary containment equipment or in devices, like safety centrifuge cups or biosafety cabinets (BSC). Some other primary barriers that must be used are face protection, splash shields, gloves and gowns. Potential environment contamination can be removed by the availability of secondary barriers like hand washing sinks and waste decontamination facilities.

Biosafety Level 3

Practices, safety equipment, and facility design and construction are applicable to clinical, diagnostic, teaching, research, or production facilities in which work is done with indigenous or exotic agents with a potential for respiratory transmission and which may cause serious and potentially lethal infection. Mycobacterium tuberculosis, St. Louis encephalitis virus, and Coxiella burnetii are representative of the microorganisms assigned to this level. Primary hazards to personnel working with these agents relate to autoinoculation, ingestion, and exposure to infectious aerosols.

At Biosafety Level 3, primary and secondary barrier are emphasized in order to protect people working in contiguous areas, the community, and the environment from exposure to infectious aerosols. For example, all laboratory manipulations must be carried out in a BSC or other enclosed equipment, like a gas- tight aerosol generation chamber. Secondary barriers for Level 3 include controlled lab access and ventilation requirements to reduce the release of infectious aerosols from the lab.

Bio-safety Level 4

The design & construction of facility, processes and safety equipment are applicable for work with hazardous and exotic agents that have a high personnel risk of life-threatening disease, which may be transmitted through the aerosol route and for which there is no vaccine or therapy available. Agents with a close or similar antigenic relationship to Biosafety Level 4 agents must also be handled at level 4. After obtaining sufficient data, work with these agents might be continue at level 4 or at a lower level. Bio-safety Level 4 can manipulate viruses, like Marburg or Congo- Crimean hemorrhagic fever.

The primary hazards to laboratory workers working with Biosafety Level 4 agents include mucous membrane, autoinoculation, respiratory exposure to infectious aerosols and broken skin exposure to infectious droplets. Manipulating potentially infectious diagnostic materials, isolates, and naturally or experimentally infected animals has a high risk of exposure and infection to lab workers, the community as well as the environment.

Laboratory workers can isolate themselves from aerosolized infectious materials primarily by working in a Class III BSV or in a full-body, air-supplied, positive-pressure personnel suit. The Biosafety Level 4 facility is also a separate building or fully isolated zone with complex, in which there must be waste management systems and specialized ventilation requirements to prevent release of viable agents to the environment.

Bio-safety Cabinet Classification

This standard covers Class II Biosafety cabinetry, but Class I and Class III cabinets are also commercially available. It is feasible to use biosafety cabinets with biological agents assigned to biosafety levels 1 to 4, based on the facility design as mentioned in Biosafety in Microbiological and Biomedical Laboratories. It must be noted that BSL 4 agents must only be used in Maximum Containment Laboratories and that Class I and Class II biosafety cabinets are only used in Maximum Containment Laboratories along with positive pressure containment suits.

Class I Bio-safety Cabinet

A ventilated cabinet for personnel and environmental protection, having an un-recirculated inward airflow away from the operator that exhausts all air to the atmosphere after filtration through a HEPA filter. Class I cabinets are ideal for work where there is no requirement for product protection.

Class II Bio-safety Cabinet

A ventilation cabinet is ideal for protection of personnel, environment and product. The cabinet with an open front with inward airflow protects personnel, downward HEPA filtered laminar airflow protects product, and HEPA filtered exhausted air protects environment.

Class II Type A1 Cabinets (formerly designated Type A)

The work access opening enables to maintain minimum average inflow velocity of 75 ft/min (0.38 m/s).

The cabinets have HEPA filtered downflow air that is a portion of both downflow and inflow air from a common plenum (i.e., a plenum from which some air portion is exhausted from the cabinet and the remaining air is supplied to the work area).

Class II Type B1 Cabinets

A completely enclosed, proper ventilated cabinet is of leak-tight construction. Attached rubber gloves are used to conduct operations in the cabinet. Negative air pressure of 0.50” WG (120 Pa) is maintained in the cabinet. HEPA filters are used for drawing the downflow air into the cabinet. Either double HEPA filtration or HEPA filtration and incineration can be used for treating the exhaust air.

Biosafety levels

The integration of laboratory processes & techniques, laboratory facilities and safety equipment needed for performing operations and prevent the hazard posed by the infectious agents and the lab operations. In Microbiological and Biomedical Laboratories, several biosafety levels are needed to be taken.

Biosafety Level 1

Processes, facility design, safety equipment and construction are right for undergraduate and secondary educational training and teaching laboratories as well as for other labs in which work is carried out with defined, characterized strains of microorganisms that are not hepatitis virus, and exempt organisms under the NIH Guidelines for Research Involving Recombinant DNA Molecules represent those microorganisms that meet such criteria. Many agents that are not linked with diseases processes in humans are, however, opportunistic pathogens and might cause infection in the human beings, including young, the elderly, and immune deficient/ suppressed. Biosafety Level 1 basically represents a basic level of containment in which standard microbiological practices are to be carried out with no recommendation of special primary or secondary barriers, other than a sink for hand washing.

Biosafety Level 2

Processes, facilities and equipment are applicable to several facilities, including clinical, diagnostic, teaching, etc., in which work is carried out with indigenous moderate-risk agents present in the community and linked with human disease of varying severity. The agents can be safely used in activities carried out on the open bench with good microbiological techniques, provided the low likeliness of producing aerosols. The Salmonellae and Toxoplasma spp., Hepatitis B virus, Human Immunodeficiency Virus (HIV) represent microorganisms assigned to this containment level.

Bio-safety Level 2 is suitable if the work has to be done with any human-derived blood, body fluids, tissues, or primary human cell lines where one might be not aware of the presence of an infectious agent. (Laboratory workers who work human-derived materials should refer to the OSHA Bloodborne Pathogen Standard for specific required precautions.) The primary hazards to lab workers working with aforementioned agents may include accidental percutaneous, ingestion of infectious materials or mucous membrane exposures. Workers must take precaution with using sharp instruments or contaminated needles.

Even though organisms periodically manipulated at Biosafety Level 2 are unknown to be transmissible by the aerosol route, processes with aerosol or high splash potential, which may elevate the risk of workers exposure, must be carried out in primary containment equipment or in devices, like safety centrifuge cups or biosafety cabinets (BSC). Some other primary barriers that must be used are face protection, splash shields, gloves and gowns. Potential environment contamination can be removed by the availability of secondary barriers like hand washing sinks and waste decontamination facilities.

Biosafety Level 3

Practices, safety equipment, and facility design and construction are applicable to clinical, diagnostic, teaching, research, or production facilities in which work is done with indigenous or exotic agents with a potential for respiratory transmission and which may cause serious and potentially lethal infection. Mycobacterium tuberculosis, St. Louis encephalitis virus, and Coxiella burnetii are representative of the microorganisms assigned to this level. Primary hazards to personnel working with these agents relate to autoinoculation, ingestion, and exposure to infectious aerosols.

At Biosafety Level 3, primary and secondary barrier are emphasized in order to protect people working in contiguous areas, the community, and the environment from exposure to infectious aerosols. For example, all laboratory manipulations must be carried out in a BSC or other enclosed equipment, like a gas- tight aerosol generation chamber. Secondary barriers for Level 3 include controlled lab access and ventilation requirements to reduce the release of infectious aerosols from the lab.

Bio-safety Level 4

The design & construction of facility, processes and safety equipment are applicable for work with hazardous and exotic agents that have a high personnel risk of life-threatening disease, which may be transmitted through the aerosol route and for which there is no vaccine or therapy available. Agents with a close or similar antigenic relationship to Biosafety Level 4 agents must also be handled at level 4. After obtaining sufficient data, work with these agents might be continue at level 4 or at a lower level. Bio-safety Level 4 can manipulate viruses, like Marburg or Congo- Crimean hemorrhagic fever.

The primary hazards to laboratory workers working with Biosafety Level 4 agents include mucous membrane, autoinoculation, respiratory exposure to infectious aerosols and broken skin exposure to infectious droplets. Manipulating potentially infectious diagnostic materials, isolates, and naturally or experimentally infected animals has a high risk of exposure and infection to lab workers, the community as well as the environment.

Laboratory workers can isolate themselves from aerosolized infectious materials primarily by working in a Class III BSV or in a full-body, air-supplied, positive-pressure personnel suit. The Biosafety Level 4 facility is also a separate building or fully isolated zone with complex, in which there must be waste management systems and specialized ventilation requirements to prevent release of viable agents to the environment.

Bio-safety Cabinet Classification

This standard covers Class II Biosafety cabinetry, but Class I and Class III cabinets are also commercially available. It is feasible to use biosafety cabinets with biological agents assigned to biosafety levels 1 to 4, based on the facility design as mentioned in Biosafety in Microbiological and Biomedical Laboratories. It must be noted that BSL 4 agents must only be used in Maximum Containment Laboratories and that Class I and Class II biosafety cabinets are only used in Maximum Containment Laboratories along with positive pressure containment suits.

Class I Bio-safety Cabinet

A ventilated cabinet for personnel and environmental protection, having an un-recirculated inward airflow away from the operator that exhausts all air to the atmosphere after filtration through a HEPA filter. Class I cabinets are ideal for work where there is no requirement for product protection.

Class II Bio-safety Cabinet

A ventilation cabinet is ideal for protection of personnel, environment and product. The cabinet with an open front with inward airflow protects personnel, downward HEPA filtered laminar airflow protects product, and HEPA filtered exhausted air protects environment.

Class II Type A1 Cabinets (formerly designated Type A)

The work access opening enables to maintain minimum average inflow velocity of 75 ft/min (0.38 m/s).

The cabinets have HEPA filtered downflow air that is a portion of both downflow and inflow air from a common plenum (i.e., a plenum from which some air portion is exhausted from the cabinet and the remaining air is supplied to the work area).

- The cabinets from the exhaust canopy can exhaust HEPA filtered air back into the lab or to the environment.

- The cabinets have positive pressure contaminated ducts and plenums away from negative pressure plenums.

- Do not use Type A1 cabinets to work with volatile radionuclides and volatile toxic chemicals.

- Class II, Type A2 Cabinets (formerly referred to as Type B3)

- The work access opening enables to maintain a minimum average inflow velocity of 100 ft/min (0.5 m/s).

- The cabinets have HEPA filtered downflow air comprising both, downflow and inflow air from a common plenum.

- The cabinets might use an exhaust canopy to exhaust HEPA filtered air back into the laboratory or to the environment.

- The cabinets have all biologically contaminated ducts and plenums under negative pressure or are surrounded by ducts and plenums under negative pressure.

- Type A2 cabinets are mainly applied for operations with limited quantities of volatile toxic chemicals and radionuclides in tracer amounts needed as an adjunct to microbiological studies should be exhausted through exhaust canopies that function properly.

Class II Type B1 Cabinets

- The cabinets through the work access opening a minimum average inflow velocity of 100 ft/min (0.5 m/s).

- The cabinets have HEPA filtered downflow air that composes uncontaminated re-circulated inflow air.

- The cabinets have a dedicated duct to exhaust most of the contaminated downflow air exhausted to the atmosphere after passing through a HEPA filter.

- These have biologically contaminated ducts & plenums under negative pressure or surrounded by ducts and plenums under negative pressure.

- Use Type B1 cabinets for work treated with little quantities of volatile toxic chemicals and tracer amounts of radionuclides needed as an adjunct to microbiological studies in case the work is carried out in the cabinet’s direct exhausted portion, or if the chemicals or radionuclides will not interfere with the work while recirculated in the downflow air.

- The cabinets are useful in maintaining a minimum average inflow velocity of 100 ft/min (0.5 m/s) from the work access opening.

- The cabinets have HEPA filtered downflow air from either lab or outside air i.e., recirculation of downflow air is not done from the cabinet exhaust air.

- Once filtered through a HEPA filter, all inflow and downflow air is exhausted to the atmosphere, without recirculating in the cabinet or return to the lab.

- All cabinets have contaminated ducts and plenums under negative pressure or surrounded by directly exhausted negative pressure ducts and plenums.

- Type B2 cabinets can be used for work with volatile radionuclides and toxic chemicals needed as adjuncts to microbiological studies.

A completely enclosed, proper ventilated cabinet is of leak-tight construction. Attached rubber gloves are used to conduct operations in the cabinet. Negative air pressure of 0.50” WG (120 Pa) is maintained in the cabinet. HEPA filters are used for drawing the downflow air into the cabinet. Either double HEPA filtration or HEPA filtration and incineration can be used for treating the exhaust air.

Other Products in 'Biosafety Cabinets' category

Get in touch with us